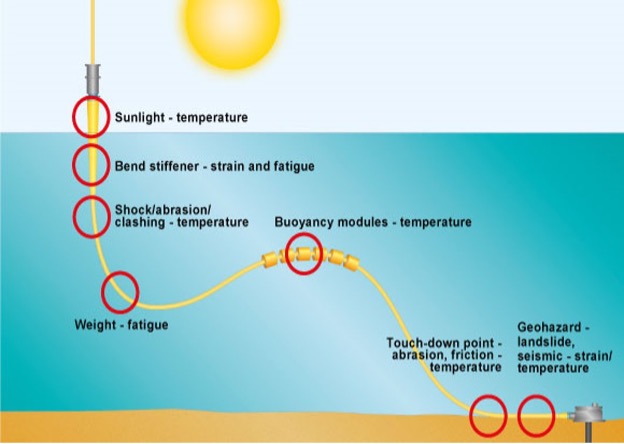

UMBILICALS AND DISTRIBUTION

The primary objective of the subsea umbilical system is to assure that all components and subsystems of the entire subsea system come together to form a coherent, functional system that meets the project needs: Topside and subsea interfaces will be defined, Field layout drawings will be developed, including umbilical lengths and routes, Slopes will be reviewed along the selected routes and on-bottom stability assessed by the Flowline engineer, based on DNVGL-RP-F109, Ancillary equipment for the umbilical system will be confirmed with the Umbilical supplier: • Bend restrictors • Terminations • Centralizers • Hang-off flanges.